Deploy with Confidence: A SaaS Pipeline Overhaul

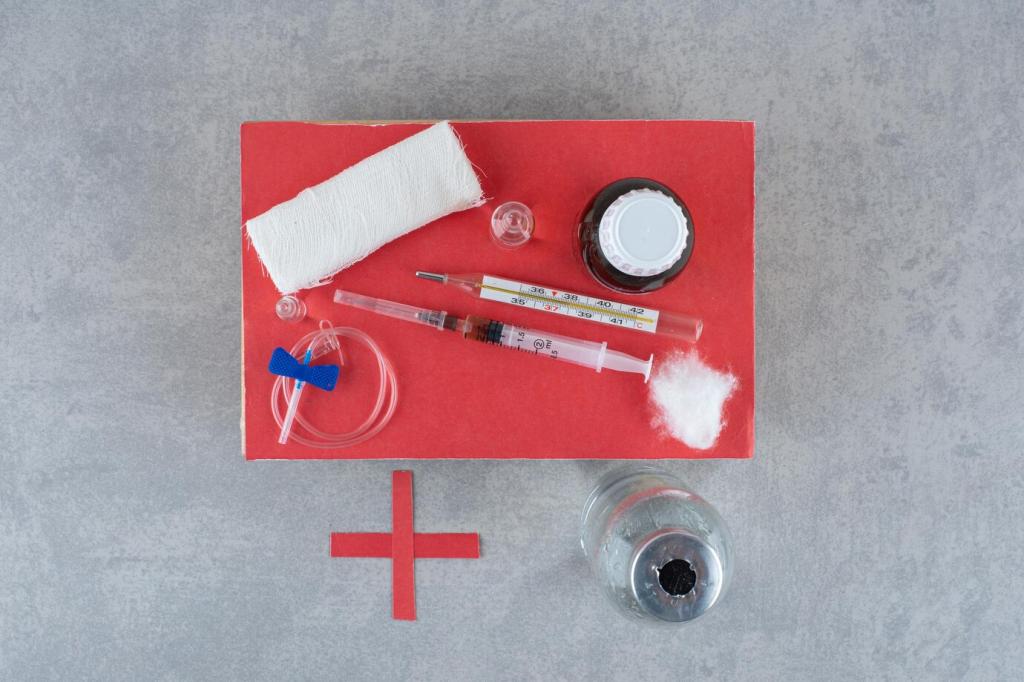

Deployments were weekend marathons guarded by a single release engineer, with manual checklists and fragile rollbacks. Lead time from commit to production averaged two days, and change failure rate hovered above 15%. The team feared shipping, so work piled up into risky batches that amplified scope, stress, and recovery time.

Deploy with Confidence: A SaaS Pipeline Overhaul

They adopted trunk-based development with small, frequent merges, added parallelized tests, and instrumented services with tracing and golden signals. Feature flags enabled gradual rollouts and instant kill switches. Canary releases caught regressions early, while dashboards made reliability a shared ritual, not a specialty. Documentation lived beside code to keep truth current.